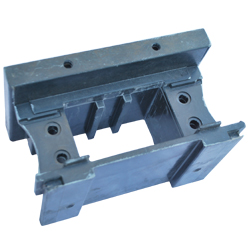

Compression Moulded Components

We are Manufacturer, Supplier, Exporter of Compression Moulded Components (P.F.) Phenol Formaldehyde, Phenol formaldehyde compression moulding, Phenolic Moulding Compound For Automotive, Automotive Engine Parts, Electrical Insulators, Industrial Machinery Parts From Ahmednagar, Maharashtra, India.

- Compression Moulded Components (P.F.) are high-strength, thermosetting moulded products widely used in electrical, automotive, and industrial applications.

- These components are manufactured using PF (Phenol Formaldehyde) resin, which provides excellent mechanical strength, heat resistance, and electrical insulation properties.

- The compression moulding process ensures precise shaping, uniform density, and minimal shrinkage, making these components ideal for high-performance applications.

- Compression Moulded Components (P.F.) offer superior resistance to chemicals, moisture, and high temperatures, ensuring durability and reliability in demanding environments.

- They are extensively used in switchgear, circuit breakers, automotive assemblies, and various industrial machinery, where strength and stability are critical.

Salient Features:

- High Mechanical Strength And Dimensional Stability

- Excellent Electrical Insulation Properties

- Superior Heat Resistance And Thermal Stability

- Resistant To Moisture, Chemicals, And Corrosion

- Precise Moulding With Uniform Density

- Low Shrinkage And High Impact Resistance

- Suitable For High-Performance And Heavy-Duty Applications

Applications:

- Electrical Insulators, Terminal Blocks, And Switchgear Components

- Circuit Breakers, Fuse Holders, And Relay Housings

- Automotive Components Such As Engine Covers, Gaskets, And Panels

- Industrial Machinery Parts Requiring High Heat And Electrical Resistance

- Aerospace And Defense Equipment Components

- Consumer Appliances And Power Tool Housings

- High-Temperature And High-Voltage Applications