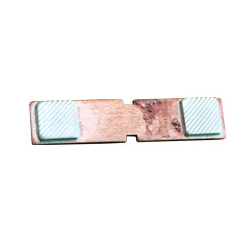

Contact Brazing

We are Manufacturer, Supplier, Exporter And Maintenance of Contact Brazing, Brazing Copper, Brazing, From Ahmednagar, Maharashtra, India.

Contact Brazing is a highly efficient joining process used for creating strong, durable, and conductive joints in electrical, automotive, and industrial applications. This process involves the controlled heating of metal surfaces to a specific temperature, allowing the filler metal to flow and bond without melting the base metals. Contact Brazing ensures high-strength connections with excellent thermal and electrical conductivity, making it ideal for critical components.

The method is widely used for joining Copper (Cu), SS (Stainless Steel), Brass (Cu-Zn Alloy), and Aluminum (Al). It offers advantages such as minimal distortion, superior corrosion resistance, and a clean, flux-free process, making it suitable for precision assemblies in high-performance industries.

Salient Features:

- Strong And Durable Joints With High Mechanical Strength

- Excellent Thermal And Electrical Conductivity

- Minimal Distortion And Precise Bonding

- Superior Corrosion And Oxidation Resistance

- Suitable For Various Metals Including Cu (Copper), SS (Stainless Steel), And Al (Aluminum)

- Clean And Flux-Free Process For High-Purity Applications

- High Wear And Fatigue Resistance

Applications:

- Electrical Contacts, Switchgear, And Busbar Connections

- Automotive Components Such As Radiators, Heat Exchangers, And Sensors

- Aerospace And Defense Equipment Assemblies

- Power Transmission And Distribution Systems

- Industrial Machinery And Tooling Components

- Consumer Electronics And Precision Instrumentation

- Medical Devices And High-Performance Engineering Components